As we move through 2026, the definition of folding cartons has been rewritten. It is…

Why Northeast Brands are Switching to Wet-Strength Paperboard

For decades, frozen food and refrigerated retail products relied on plastic trays and poly-coated boxes that were difficult to recycle. But with new regulations sweeping the Northeast (and shifting consumer sentiment), the demand for sustainable alternatives is non-negotiable.

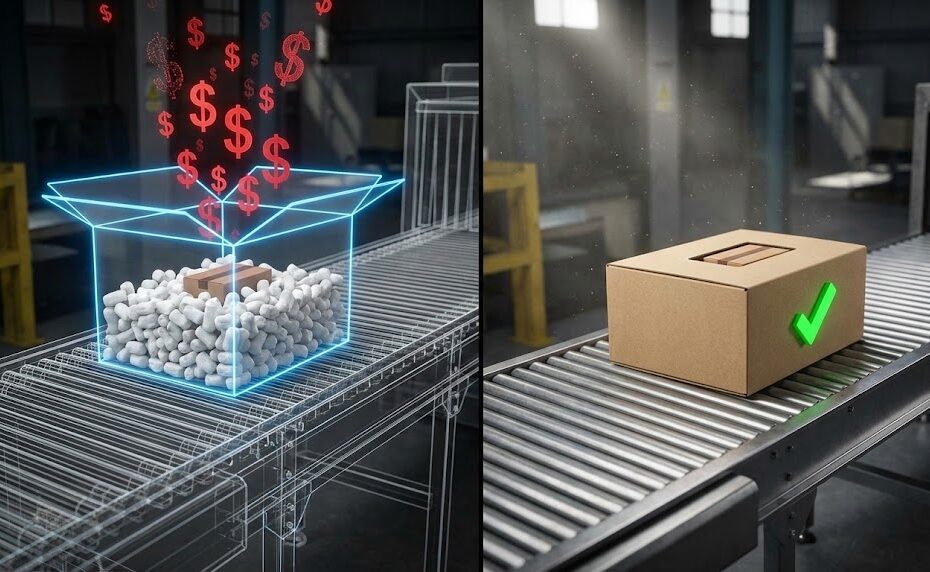

The Challenge: Moisture vs. Paper Standard paperboard acts like a sponge in high-humidity environments (like a freezer). It gets soggy, loses structural integrity, and fails. This is why brands stuck with plastic for so long.

The Solution: Wet-Strength Carrier Board (CUK) Rice Packaging specializes in converting Coated Unbleached Kraft (CUK) and Wet-Strength SBS. These materials are engineered with a resin bond within the paper fibers that repels water absorption while remaining recyclable.

Why Switch Now?

-

The “Plastic Tax”: Many states are introducing Extended Producer Responsibility (EPR) laws that tax single-use plastics. Paperboard often bypasses these fees.

-

Printability: You cannot print high-resolution graphics directly onto a black plastic tray. You can, however, print 6-color offset lithography directly onto a wet-strength sleeve or carton, giving you 360 degrees of branding real estate.

-

Consumer Preference: A paperboard box signals “premium” and “eco-friendly” on the shelf, whereas plastic clamshells increasingly signal “waste.”

Applications:

-

Frozen Entrees: Replace plastic bowls with formed paperboard trays.

-

Beverage Carriers: 4-pack and 6-pack carriers that withstand condensation from cold cans.

-

Produce: Trays for mushrooms or berries that breathe without collapsing.

Ready to remove plastic from your supply chain? Ask us about our wet-strength board options.