As we move through 2026, the definition of folding cartons has been rewritten. It is…

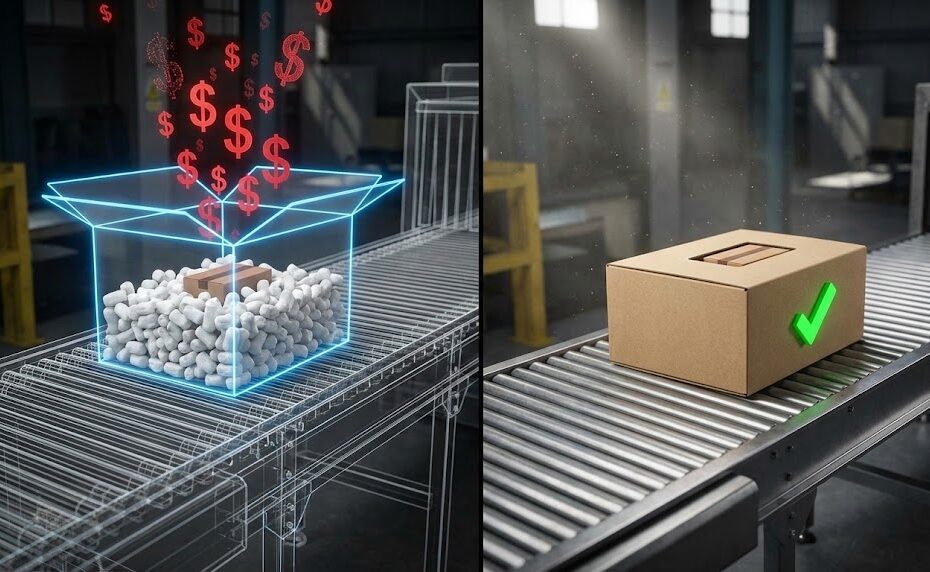

How Custom Packaging Design Lowers Shipping Costs

If you are shipping products via FedEx, UPS, or USPS, you might be paying for air—literally. Carriers no longer charge just based on weight; they charge based on Dimensional Weight (Dim Weight).

What is Dim Weight? Carriers calculate the volume of your box (Length x Width x Height) and divide it by a “divisor” (typically 139). If this “theoretical” weight is higher than the actual weight of your product, you get charged the higher rate.

-

Example: You ship a lightweight 2lb pillow in a large 18x18x18 box. The carrier might charge you as if it weighs 42lbs because of the space it takes up in the truck.

How “Stock” Boxes Hurt Your Margins Buying standard 12x12x12 boxes from a catalog often leaves 30% of the box empty. You pay to ship that empty space, AND you pay for the bubble wrap to fill it.

The Rice Packaging Solution: Structural Efficiency By engineering a custom folding carton or corrugated mailer that fits your product within 1/8th of an inch, we achieve three things:

-

Lower Dim Weight: We reduce the exterior volume, dropping you into a cheaper shipping tier.

-

Eliminate Void Fill: A tight structural fit often removes the need for peanuts or air pillows.

-

Reduced Damage: Products that don’t move inside the box don’t break.

Real World Impact: We recently helped a Northeast automotive parts supplier reduce their box volume by 20% by switching from a stock RSC box to a custom die-cut mailer, saving them over $1.50 per unit in shipping costs.

Is your packaging costing you extra at the post office? Request a structural audit today.